The Role of Cable Marking in Safe and Efficient Electrical Installations

Introduction

In complex electrical systems, cable marking is often underestimated — yet it plays a critical role in ensuring safety, clarity, and long-term reliability. Whether it’s an industrial control panel, building infrastructure, or energy distribution system, proper cable identification helps prevent costly errors, accelerates maintenance, and ensures compliance with electrical standards.

This article explains why cable marking is essential and how to choose the right method and materials for your project.

Why Cable Marking Matters

Proper cable identification improves both safety and workflow. Here’s how:

- Prevents connection errors

Clearly labeled cables reduce the risk of miswiring and short circuits. - Simplifies troubleshooting and maintenance

Technicians can quickly locate and identify cables, reducing downtime. - Supports future upgrades

Well-marked cables make system expansions or modifications faster and safer. - Ensures regulatory compliance

Standards like IEC 60445, ANSI, and OSHA often require proper labeling for control panels and electrical systems.

Where Cable Marking Is Used

Cable marking is important in various environments, including:

- Electrical panels and switchboards

- Industrial automation systems

- Construction sites and building infrastructure

- Data centers and telecommunication systems

- Renewable energy facilities

Common Types of Cable Marking Solutions

1. Heat Shrink Sleeves

Printed sleeves that shrink around the cable when heated. Durable and commonly used in industrial environments.

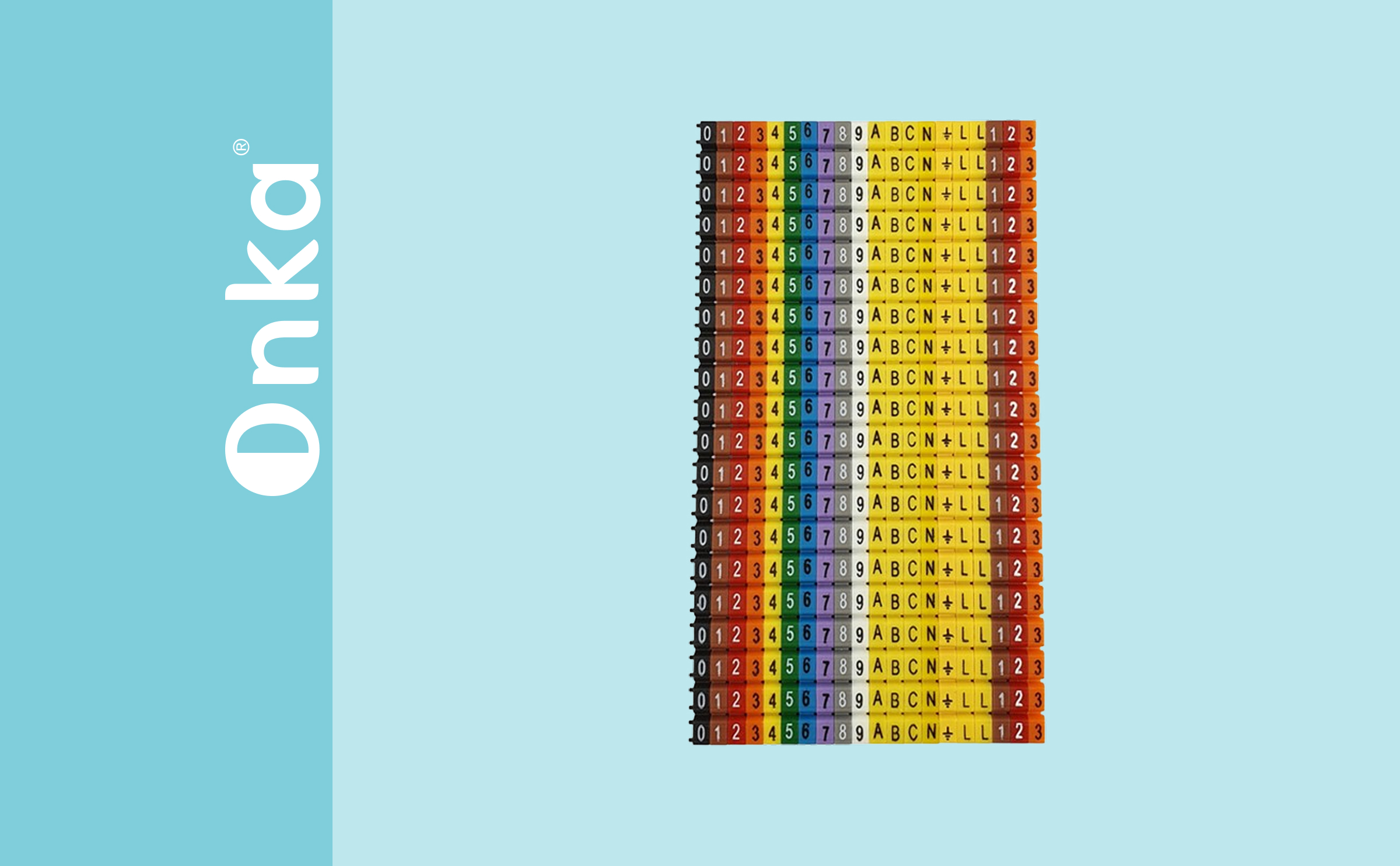

2. Clip-On or Slide-On Markers

Pre-printed or blank plastic markers that clip onto wires. Easy to install without tools.

3. Adhesive Labels

Self-adhesive stickers for fast and flexible labeling, suitable for low-vibration areas.

4. Wrap-Around Labels

Wrap completely around the cable, offering visibility from multiple angles. Often used for thicker cables.

5. Laser-printed or Engraved Tags

High-durability metal or plastic tags for harsh environments, including high temperatures and chemicals.

Choosing the Right Cable Marking Method

When selecting a cable marking system, consider the following:

- Operating environment

Heat, moisture, and chemical exposure require durable materials like heat-shrink or metal tags. - Cable size and type

Ensure the marker fits securely without slipping or damaging the insulation. - Visibility requirements

Use color coding and large fonts for high-traffic or high-voltage areas. - Installation time and budget

Clip-on markers are quick and affordable, while engraved tags are more durable but costlier.

Best Practices for Effective Cable Marking

- Use standardized abbreviations and numbering for consistency

- Place markers close to connectors or terminations

- Avoid placing labels where they may be damaged by heat or abrasion

- Maintain a reference document or wiring diagram linked to the labeling system

- Use high-quality printing to prevent fading over time

Conclusion

Cable marking is not just a formality — it’s a foundational element of safe, efficient, and future-ready electrical installations. The right labeling system ensures operational clarity, minimizes errors, and supports compliance with industry standards.

Looking for high-quality cable marking solutions?

Explore our range of ONKA cable marking products, designed for durability, flexibility, and fast installation in any environment.